Natural stone is mined from the Earth, in large quarries. The different mineral composition of each stone, forming process, and quarry location, is what determines the type of material naming and colouration. Major stone classifications for design use are Granite, Marble, Limestone and Slate.

Blocks of stone are mined using carefully drilled holes and explosives to separate blocks of stone with desired sizes, from the bedrock. The blocks are then toppled over onto a soft bedding surface by machinery, and transported to the factory for further processing. One of our favourite videos illustrating this process can be found on NOWNESS here:

Once at the factory, blocks are sliced with diamond-tipped saws. Typically these blocks are cut into 2cm or 3cm thickness which are the most popular thicknesses on the market for countertop, interior and exterior cladding applications. Thicker pieces can also be produced for special-projects, such as columns, fireplaces, bathtubs and sinks or other sculptural works. Improvements in technology have allowed for more rapid production of these slabs and thus more availability on the worldwide market.

Once the desired slabs have been cut, the next step is surface finishing. Different surface finishes are possible, with polished being the most popular. Circular brushes and polishing pads work away at the material surface of each slab individually. Each block is identified by serial numbers, allowing customers to understand which slabs have been cut from which part of the quarry. Within the same block, there will be a certain consistency in minerology, meaning similar grain structure and colour. We like to think of slabs from the same block like sliced bread; where each loaf is sliced, and as you move from the first slice to the last, the ingredients, look and taste are very similar with little variation.

In today’s designs, we often see stone slabs that are installed as bookmatched, meaning the slabs are side-by-side and are mirrored to one another, creating striking patterns and great visual appeal. To achieve this, the slabs within each block are polished on opposite sides. For example slab number 1 will be polished on the front, and slab number 2 will be polished on the backside so when they are placed together, it creates a bookmatch effect. This has become standard practice from the suppliers, as bookmatched slabs are now widely considered as the norm.

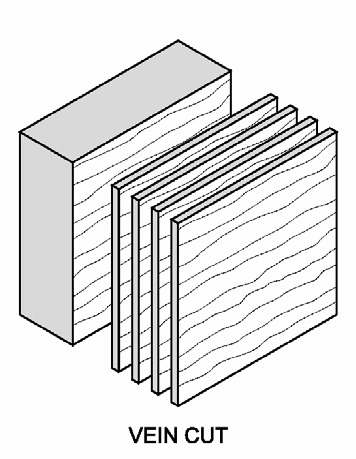

Another way to cut the blocks is Veincut or Crosscut. This refers to slab production in the vertical-sense for Veincut, exposing the layers of mineral veins and in horizontal-sense for Crosscut, exposing the different mineral deposits in a more mottled and cloud like fashion. When this is done with the same material, vastly different outcomes of slabs are possible.

These slabs are then packaged in crates and shipping containers, supplying markets all over the world!

Comentarios